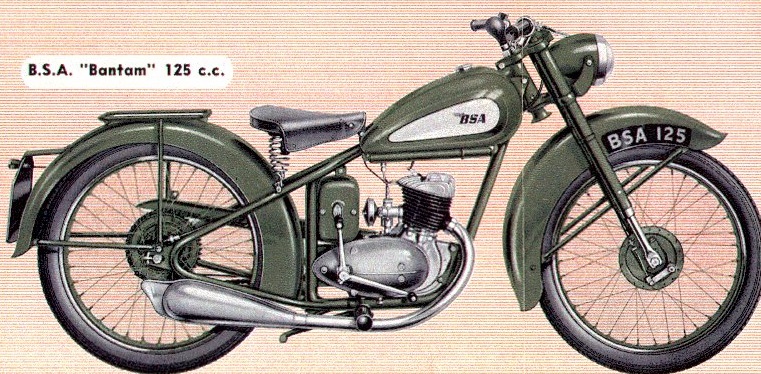

The BSA Bantam (1948-1971) was by far the longest running motorcycle model produced by the Birmingham based company. This was because, unlike the 4-stroke motorcycles produced that went from side valve to overhead valve and from pre-unit to unit construction models over that timescale, the 2-stroke Bantam engine remained largely the same other than increasing in capacity from 125 cc to 175 cc and eventually acquiring a 4-speed gearbox.

BSA Bantam Engine Design

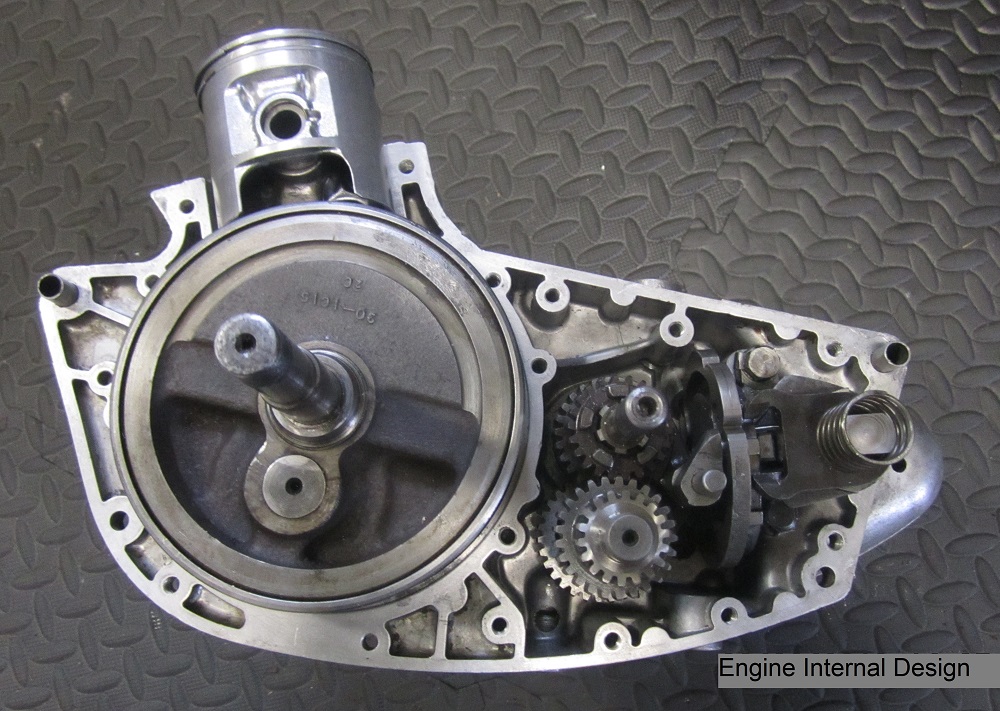

The pictures below are from my 1968 D14/4 engine which represents the final form of the Bantam engine. These engines use a cast aluminium crankcase which is split vertically and are held together by a large number of screws.The crankshaft is built up using a needle roller big-end bearing and large round cast iron flywheels with the counter weights cast in. The piston is equipped with two scraper rings and, on the D14 engine, a needle bearing small-end is used.

Given that the Bantam engine operates as a two-stroke, the crankcase acts as the transfer chamber for the fuel mixture and therefore has to incorporate seals for the crankshaft. On the D14 engine, there is one ball bearing on the left-hand end of the crankshaft with both an inner and outer seal, and two ball bearings on the right-hand end with an inner seal (the primary chaincase cover provides the outer seal). The crankshaft bearings are lubricated via gearbox oil via small oilways drilled through the crankcases.

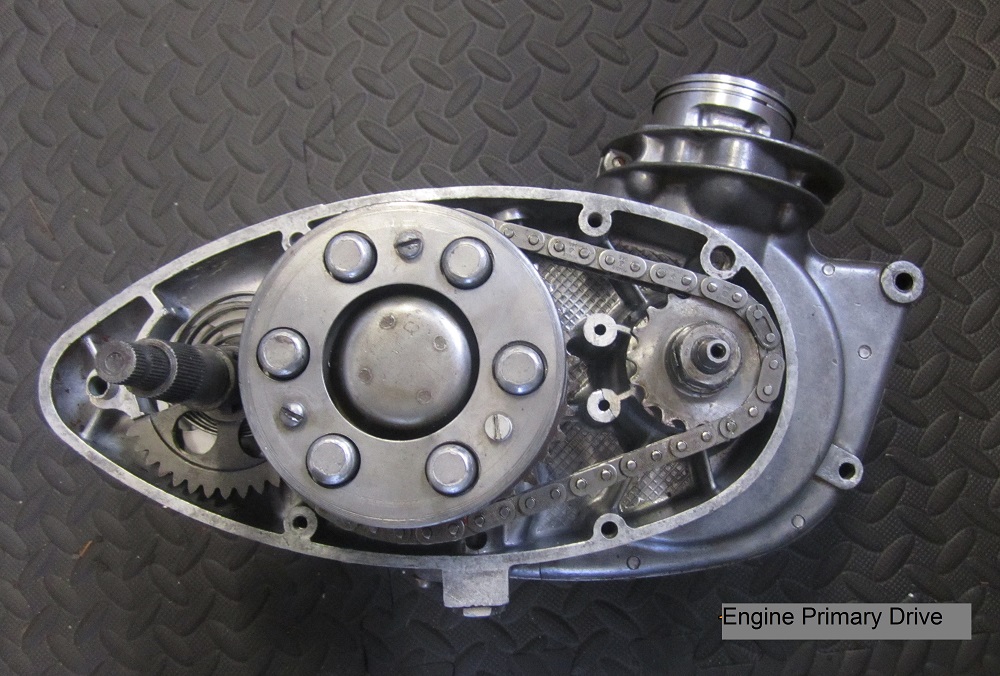

The D14 engine is equipped with a four speed gearbox operated via a camplate, twin selector forks, a selector quadrant and a selector plate linked to the gear change lever via a spindle. On Bantam engines the clutch is on the right-hand end of the gearbox mainshaft with the primary chaincase also on the right-hand side. The clutch is driven via a chain by the crankshaft sprocket and uses three driven plates and four friction plates. Six springs are used to compress the clutch plates with the clutch pressure plate held in place with the clutch basket via a large circlip.

Underneath the clutch basket is a spring loaded kickstart pinion which engages the the clutch via ratchet teeth. The pinion is driven via the kickstart quadrant which is equipped with a return spring. On teh D14 engine the contact breaker assembly is located under an access plate in the primary chaincase cover. The operating cam fits into the end of the crankshaft via a tapered hole and bolt.

The D14 engine is fitted with a six-pole Wipac alternator with the rotor keyed into the left-hand end of the crankshaft. The stator is held in place via three studs from the crankcase which also hold the left-hand inner cover in place via nuts. The inner cover also contains the clutch operating mechanism at the rear which is operated via a lever and clutch cable, the latter being slotted into the bottom of the inner cover. The clutch mechanism is adjusted via an inspection hole in the outer left-hand cover.

The Bantam engines used a cast iron cylinder and a alloy cylinder head with offset spark plug for all engines up to including the D14 but with central spark plug for the later engines. The D1-D7 engines were similar to that of the D14 engine with the main difference being the use of a three-speed gearbox. Since there is only one pair of sliding gears needed for this, the gearchange mechanism was greatly simplified compared with that for the later four-speed models. The D1-D7 engines all used a small-end bush which was changed to a needle bearing on the D10 and later models. The D1-D3 models used only two seals on the crankshaft relying on Petroil (oil added tot the petrol) to lubricate the three main bearings. The use of gearbox oil to lubricate the mains was introduced in the D5 model along with the additional left-hand crankshaft seal needed.

In the earlier D1-D5 engines, a Wipac flywheel magneto and generator was used mounted on the left-hand end of the crankshaft with the stator and clutch mechanism supported by a separate casting. The contact breaker points were mounted on the alternator stator and were enclosed by a small round cover. On the D7, a similar arrangement was used but an outer cover was fitted to enclose both the generator cover and the clutch mechanism. Magneto ignition was changed to coil ignition in the D10 model which also involved moving the contact breaker points to the right-hand end of the crankshaft accessible via a round cover in the chaincase cover.

D1 Bantam (1948-1963)

The BSA D1 Bantam was first launched in 1948 and was based on the use of the pre-war German 125 cc 2-stroke DKW RT125 single cylinder engine that had been acquired as part of the war reparations. The engine used by BSA was effectively a mirror image of the DKW engine to place the gearchange and kickstart on the right-hand side following normal British practice. It used a 3-speed gearbox in unit with the engine.

The engine had a bore and stroke of 52 mm x 58 mm, a capacity of 123 cc and a compression ratio of 6.5:1 . It used a cast iron cylinder and alloy cylinder head. The D1 Bantam originally used a rigid frame together with a simple set of telescopic front forks with internal springs but no damping. The bracket for the headlight was bolted to the lower fork yoke. The 2.75″ x 19″ wheels used 5″ offset brake hubs front and back. The front mudguard was fixed to the upper fork legs and was deeply valanced. The rear mudguard had a deep valence at the front tapering towards the rear. The rear mudguard was largely supported by the rear carrier stays.

A single sprung saddle was used but pillion footrest could be fitted and a simple pad added to the rear carrier. Under the saddle was mounted a small tool box. The original Bantam used a silencer comprising of two shaped pressings welded together. It could not be taken apart and therefore suffered from clogging up with oil deposits from the exhaust gases. The 1.75 gallon petrol tank was made from two pressings seam welded to a centre section. The petrol cap included a measure for the 2-stroke oil.

The earlier D1 Bantams used Wipac electrics and direct lighting but included a 3V battery in the headlight shell for the parking lights. The bike was finished in Mist Green that later became known as Bantam Green. In rigid frame form, the D1 continued to the end of the 1955 season.

The original D1 was not without problems that included weak electrics. These were mainly overcome in 1950 with a larger generator. At the same time, a number of different versions were offered including with a plunger frame and with Lucas electrics. The plunger frame version was produced with Wipac electrics until the end of the 1963 season, while the plunger frame version with Lucas electrics continued to the end of 1953.

D3 Bantam (1954-57)

D3 Bantam (1954-57)

The D3 Major version of the Bantam was introduced in 1954 with the main change over the D1 being an increase in engine capacity to 150 cc. The greater capacity was achieved using the same stroke but with an increase in bore from 52 to 57 mm.

The D3 was originally produced with a plunger frame but this was changed in 1956 to a swinging arm frame. This used a single loop frame with a bolt on rear sub frame with the swinging arm pivoting using Silentbloc bushes. The D3 Bantam was fitted with a toolbox on one side and a matching cover on the other side with the battery carrier in between. The finish on all D3 models was in Pastel Grey with yellow tank panels.

D5 Bantam (1958)

The D3 Bantam was replaced by the D5 in 1958 with the main change being to an increase in capacity to 172 cc achieved with a bore and stroke of 615 mm x 58 mm. The other change was to 3.00 x 18″ wheels back and front.

Changes were also made to the engine to increase its compression ratio to 7.4:1 and the addition of a caged roller bearing big-end. The sealing of the crankshaft also changed with additional seals added inboard of the main bearings to isolate them from the crankcase. Holes were drilled in the cases to allow gearbox oil to provide the lubrication of the main bearings.

The cycle parts were little changed from the D3 except for the petrol tank which increased in capacity to 2 gallons. The finish was in Baynard crimson or black with ivory tank panels.

D7 Bantam (1959-66)

The D5 Bantam was only produced for one year before being replaced by the D7 Super in 1959. This had the same capacity of 172 cc. This used the same engine as the D5 but with the addition of a further cover on the left-hand side to enclosed the magneto and clutch. In 1962 a change was made to replace the small-end bush with a needle roller.

However, the cycle parts were all new with a revised sub-frame bolted to a modified main loop. The Silentbloc bushes for the swinging arm were replaced by bronze bushes and a pivot pin pressed into the main frame lug. The front suspension was changed to hydraulic fork legs based on those of the Triumph Tiger Cub with a similar nacelle added to cover the top of the fork legs and to house the speedometer. The D7 Bantam continued with 3 x 18″ wheels but the original pressed steel hubs were replaced by Tiger Cub cast hubs.

Under the dual seat, the tool box and side cover were connected via a central panel to better enclose the space around the battery and electrics. The D7 frame parts were painted black with the tinware painted in Royal Red with the petrol tank having ivory panels. However, an all black option was also available. The side covers were equipped with Bantam Super decals. In 1960, the colours became Signal Red, blue or black.

The D7 Super remained largely unchanged until 1964 when it was joined by a Delux version. In addition to the road models, D7 Trail and D7 Pastoral models built for off-road and export use. In 1966, the D7 Super was renamed the Silver which was intended as an economy model The D7 Delux had a much better finish which included chrome tank panels.

Bantam D10( 1966-67)

The D7 model was replaced by the D10 later in 1966 which comprised four separate models with two of them featuring a 4-speed gearbox. The D10 was very similar to the D7 but with some revised engine features. A new 6-pole Wipac alternator was added and the contact breaker points moved to right-hand end of the crankshaft with a small inspection cover added to the primary cover. The engine compression ratio was raised to 8.65:1 to give more power which necessitated an extra plate in the clutch.

Most models were fitted with an AMAL Concentric carb with a pancake type air filter. The 3-speed models were the Silver and Supreme replacing the Silver and Delux versions of the D7. The 4-speed models were the Sportsman and Bushman Pastoral, respectively, for the US and export markets. The finish D10 Silver was finished in Sapphire Blue with the Supreme me finished in Flamboyant Blue with chrome tank panels.

Bantam D14 (1968)

The D14 version of the Bantam was introduced in 1968 and came in three versions, all with 4-speed gearbox – hence the D14/4 designation. It came with a larger diameter exhaust system and a engine compression ratio ratio raised to 10:1. The three models were the D14/4 Supreme, the D14/4S Sportsman and the D14/B Bushman, the latter two fitted with heavier duty front forks.

The Supreme came with the front fork nacelle and half width wheel hubs while the Sportsman used full width hubs and had a raised exhaust system. The Bushman used the larger diameter wheels but was only equipped with the front full width hub. The available colours were the same as the D10 with an all black option for the Supreme.

For reasons that are not entirely clear, the D14 replaced the pancake air filter mounted on the carburetor as used on the D10 with a new arrangement. On the D14, the tool box was moved to the left-hand side cover and the right-hand box was used to house a large triangular air filter. The air filter box was connected to the carburetor via a long plastic tube via a hole in the inner cover. The filter was held firmly against the inner cover via a rubber band which fitted over the filter and three prongs projecting from the cover. Although the new air filter arrangement was possibly an improvement on that of the D10, the downside was that the vertical panel in front the battery on the D10 had to be dispensed with to make room for the air filter tube which meant that the space around the battery then became exposed to the elements.

Bantam D175 (1969-71)

The lifetime of the D14 was relatively short like the D10 and was replaced in 1969 by the D175. This came in just two models: the D175 Road and the D175B Bushman. These models are also referred to as the B175 but this was not the official designation.

For these models, the engine was given new casings, a modified crankshaft and the cylinder head changed to provide a central sparking plug. Both models used similar cycle parts to the earlier models with a separate headlight containing the speedometer and switches. Both models used a similar exhaust system (Bushman – high level) and both went back to using offset wheel hubs.

These were the last Bantam models produced by BSA with the road model still listed in the last major launch in 1971.

My BSA Bantam D14 Restoration

I messed around with a variety of BSA Bantams in my youth but I am not really a fan of 2-stroke motorcycles – they are simply missing the appealing low down thump and valve spring whir of a 4-stroke. Nevertheless, I had to add one to my collection and the one chosen was a 1968 D14/4.

Like many of the bikes in my collection, I bought this one a few years ago but have only just got around to restoring it. It was largely complete but the main problem was that it was fitted with a 3-speed D10 engine. Therefore, last year, I sold the D10 engine and bought a replacement D14/4 engine. The new engine was in reasonable condition with a good bore and piston but I took it apart and gave it a complete overhaul. Unlike all the other BSA bikes in my collection, the D14/4 engine is largely die cast rather than sand cast. This means that, although you can clean it up, the zinc in the alloy used gives everything a greyish finish and it is therefore difficult to achieve a really shiny polished finish especially on the engine covers.

The complete bike was stripped to its component parts. Normally, I would send all the cycle parts to be shot blasted and then powder coated but, during the corona virus lockdown, this was not an option. I therefore had to clean off all the old paint and rust by hand before spray painting with etch primer and black gloss which was an enormous amount of work.

I had previously got most of the chrome work refurbished which included the petrol tank. Most of the tinware was in reasonable condition and was therefore stripped and then re-sprayed in black. In the past, I have used masking techniques to paint on white or silver lines but, this time, I toyed with the idea of using a classic pin striping technique to paint the white lines around the edge of the mudguard, side panels and petrol tank. In the end, I decided I was not up to the job and therefore used vinyl tape to achieve the white lining. All the tinware was finished in a 2k clear coat.

The front forks were completely worn out and the stanchions deeply pitted in rust. All the components parts were therefore replaced with the lower sliders repainted and finished in a 2k clear coat. My D14 came with rear shocks from a sports model without spring covers. I therefore replaced these with a pair of authentic secondhand shocks. A special tool was made up to compress the springs in order to remove the internal collets. The shock absorbers worked fine but the external surfaces including the covers needed quite a bit of restoration work before being repainted in black and silver.

The wiring harness for my D14/4 had been hacked about very badly over the years and included modifications for a key operated ignition switch that was mounted in the left side of the the headlight shell. The actual ignition and lighting switches were in good condition and so I repaired all the wiring harness, removing the myriad of crimped connectors that had been added. One of the interesting differences between the D14 wiring harness and that of the other BSA bikes in my collection is that it uses plain colours for the wiring rather than twin coloured wires. I returned the wiring harness to factory standard although I added a separate earth wire to the back light as I am not a fan of relying on earth returns through tinware and the frame.

The biggest challenge in restoring my D14 during lock down was getting hold of a new set of rims and spokes for the wheels. I normally get them from Central Wheel Components just outside of Birmingham but this option was not available. Fortunately, I managed to buy a set of stainless wheel components off the web made by the Devon Rim Company. I had heard that these were better quality than those made by Central Wheel Components but this did not prove to be the case. I stripped the half width rims and then spray painted them in Silver Sheen and then rebuilt both wheels.

All the handlebar controls were replaced by new items, as was the seat. A surprising problem for the D14 was finding the correct pattern set of handlebars with most available being the narrow (22″) flattish bars fitted to the sports model. In the end, I had to settle for the closest design I could find. The other main challenge was finding an authentic air filter. The air filter box is on the right-hand side under the seat and originally housed a large triangular air filter with a rubber seal on the left-hand side and a metal cover on the right-hand side. These are no longer available and old ones are as rare as hens teeth. The best I could do was to acquire a secondhand air filter element that was missing the metal cover. I therefore fashioned a replacement cover and then fitted the air filter in place with a genuine rubber band. This loops over the air filter and attaches to the air box inner cover via three prongs.

I enjoyed my BSA Bantam D14 restoration although this was done under somewhat difficult circumstances due to the lockdown. The rebuild was relatively straightforward but some parts were surprisingly difficult to get hold of despite the Bantam being originally produced in larger numbers than any other model.

BSA Bantam D14/4 Specifications

BSA Bantam D14/4 Specifications

- Engine: Single cylinder, 2-stroke

- Starting: Kickstart only

- Capacity: 172 cc

- Bore/Stroke: 61.5 x 58 mm

- Compression Ratio: 10:1

- Max Power: 12.6 hp

- Carburettor: Amal R626 Concentric carburettor

- Cooling: Air cooled

- Lubrication: Dry sump

- Ignition: Coil and contact breaker points

- Transmission: 4 speed foot shift

- Final Drive: Chain

- Front Suspension: Coil spring and hydraulically damped

- Rear Suspension: Coil spring and hydraulically damped

- Front Brake: 5.5 inch drum single leading shoe

- Rear Brake: 5.5 inch drum single leading shoe

- Frame: Welded duplex

- Wheel Base 50 inch

- Seat Height: 31 inch

- Front Tyre 3.00 x 18 inch

- Rear Tyre: 3.00 x 18 inch

- Ground Clearance: 6.75 inch

- Dry Weight: 217 lb

- Fuel Tank: 1 7/8 gallons

BSA Bantam Parts Suppliers

Most BSA Bantam spare parts are relatively easy to get hold of with many good suppliers easily found on the internet. Bournemouth Bantams provide spares and other useful technical information on the BSA Bantam range. Two of the larger suppliers of BSA parts, Burton Bike Bits and Dragonfly Motorcycles, are also useful sources of Bantam spares.

30,854 total views, 111 views today